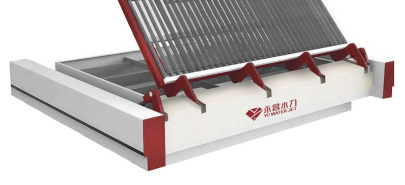

YCWJ HP Pump 3742S G-Series 2.5m*6.5m MAX5-Axis Double Gantry Water Jet Cutting Machine

Key Features & Benefits

• Dual Gantry Structure

The robust dual-gantry framework provides exceptional stability and rigidity during high-speed operation, minimizing vibration and maintaining a cutting accuracy of ±0.1 mm.

Capable of handling oversized workpieces with a maximum width of 2.5 meters and lengths up to 6.5 meters, making it ideal for large-format materials.

Adjustable head spacing (50–1000 mm) enables flexible batch processing, reducing cycle times by approximately 40% compared to single-head systems.

• High-Efficiency Pump System

Powered by the YCG-3742S ultra-high-pressure pump (420 MPa / 6000 psi, 3.7 L/min flow rate), which features a fully imported American Accustream brand intensifier, the system can cut materials up to 200 mm thick with minimal taper.

• MAX5-Axis Waterjet Cutting

The Max5 axis waterjet cutting head dynamically adjusts angles up to ±45°, ensuring edge perpendicularity on contoured surfaces for complex applications in stone, composites, and metals.

• Intelligent Control Ecosystem

Integrated with dedicated high-performance waterjet cutting software, offering real-time motion control, collision detection, and AI-powered predictive maintenance alerts to effectively minimize downtime.

Water jet cutting table

1.(1)Effective cutting area: 2500*6500mm

(2)Running Speed

X axis:0-8000mm/min

Y axis:0-8000mm/min

2.Linear guide rail: HIWIN

Ball Screw: SHAC

3.Servo System: Yaskawa(EtherCAT)

4.CNC Controller: WEIHONG

Waterjet Software: NCstudio

5. Electric parts: Schneider

6.Related cables, air circuits, and other accessories

Water jet cutting head

Bevel axis (A): ±45°

Rotary axis (C): ±540°

Control accuracy: ±0.01mm

Angle accuracy: 0.01°

Max 5 axis waterjet cutting head is based on the standard three-axis (x-axis Y-axis Z-axis) and adds the a-axis (rotation around x-axis) and the c-axis (rotation around z-axis), which can achieve large-angle deflection。By using state-of-the-art technology and Italian ECS control system, it can produce 0-±45° or more inclined cuts with a maximum rotation angle of up to ±540°.Therefore, it can achieve the effect of 3d waterjet cutting.

YCWJ-3742S-G2565/MAX5DG | |||

Parameters | Unit | G2565 | |

Efficient Cutting area | mm | 2500×6500 | |

Axis travel | X | mm | 2500 |

Y | mm | 6500 | |

Z | mm | 150-180 | |

Cutting accuracy | mm | ±0.1(upper surface) | |

Repetitive positioning accuracy | mm | ±0.025 | |

X,Y dry-run speed | m/min | 0-15 | |

Transmission Model | m/min | Ball screw & linear guide rail | |

![]()

![]()

![]()

![]()

- Intensifier assembly: Main components from Accustream

- Single-row type water filtering system

- Manual pressure regulation function

- Max pressure: 4137bar(60000psi)

- Working Pressure: 340Mpa

- Star Triangle Start

- Main motor:37KW/50HP

- Max water flow: 3.7L/Min

- Main elextric components:Schneider

- PLC:Siemens

- Extra pressure auto stop and protection

- Inlet water booster pump

- Oil temperture senser

- Inlet water pressure sensor

- Three-ply safeguard(HP overpressure/over oil temperture/inlet water pressure low)

- Electrical components: Schneider

- PLC: Siemens

- Oil pressure and inelet water pressure gauge: WIKA

- Hydraulic valves & oil pump:HYTEK

The WEIHONG-V9 water Jet cutting operation system:

Can directly support G code, PLT code format, ENG code format, DXF file format generated by various CAD/CAM software such as UG, MASTERCAM, AUTOCAD, etc Continuation of breakpoints, program skipping execution Small aperture, automatic deceleration, pause and other dfunctions for small arcs, sharp corners, and corners. Real time simulation and simulation of graphics Predict processing time, pre load processing trajectory, and dynami cally display tracking.

Cutting sample

Pictures | Specifications |

| ABRASIVE FEEDING SYSTEM Abrasive Hopper: Dynamic sand feeding Dynamic type comes over traditional type. Manual type makes the operation easier. With the help of CNC we can control abrasive automatically Abrasive Tank: It can provide the sand consumption every time after it is filled up. Capacity: 170L |

| WATER SOFTEN SYSTEM WT-2 Here are many kinds of compounds in the running water. (Calcium carbonate, carbonic acid)As the machine working, the raising of the temperature will generate some substance of the reaction of chemistry or physics-as we called it furring, which will reduce the life of the high pressure system and increase the cost. After many years’ experiences, the system can solve the problem. |

| SLUDGE REMOVAL SYSTEM SR-2 Suction pump parameters:(China) The single pump parameters Flow: 10M³/H Shoot range : 50 M Outlet pressure: 6 kgf/cm² Absord range: 7 M Maximum promise through solid part: 4.5mm Pump inlet and outlet diameter: 40mm Power:compressed air The max inlet pressure: 7 kgf/cm² The max air consume: 0.6 mm³/min Tracheal diameter:10mm Collection box: 1.6m*1.5m*1.2m |

| HYDRAULIC LOADING SYSTEM HYL400 1. Max. overturning moment load capacity: 400KG 2. The large cutting platform is hydraulically operated to overturn, which enables this hydraulic loader to load or unload an entire piece of plate while ensuring a minimum material loss and a high level of efficiency when the plate loading unit is running. |