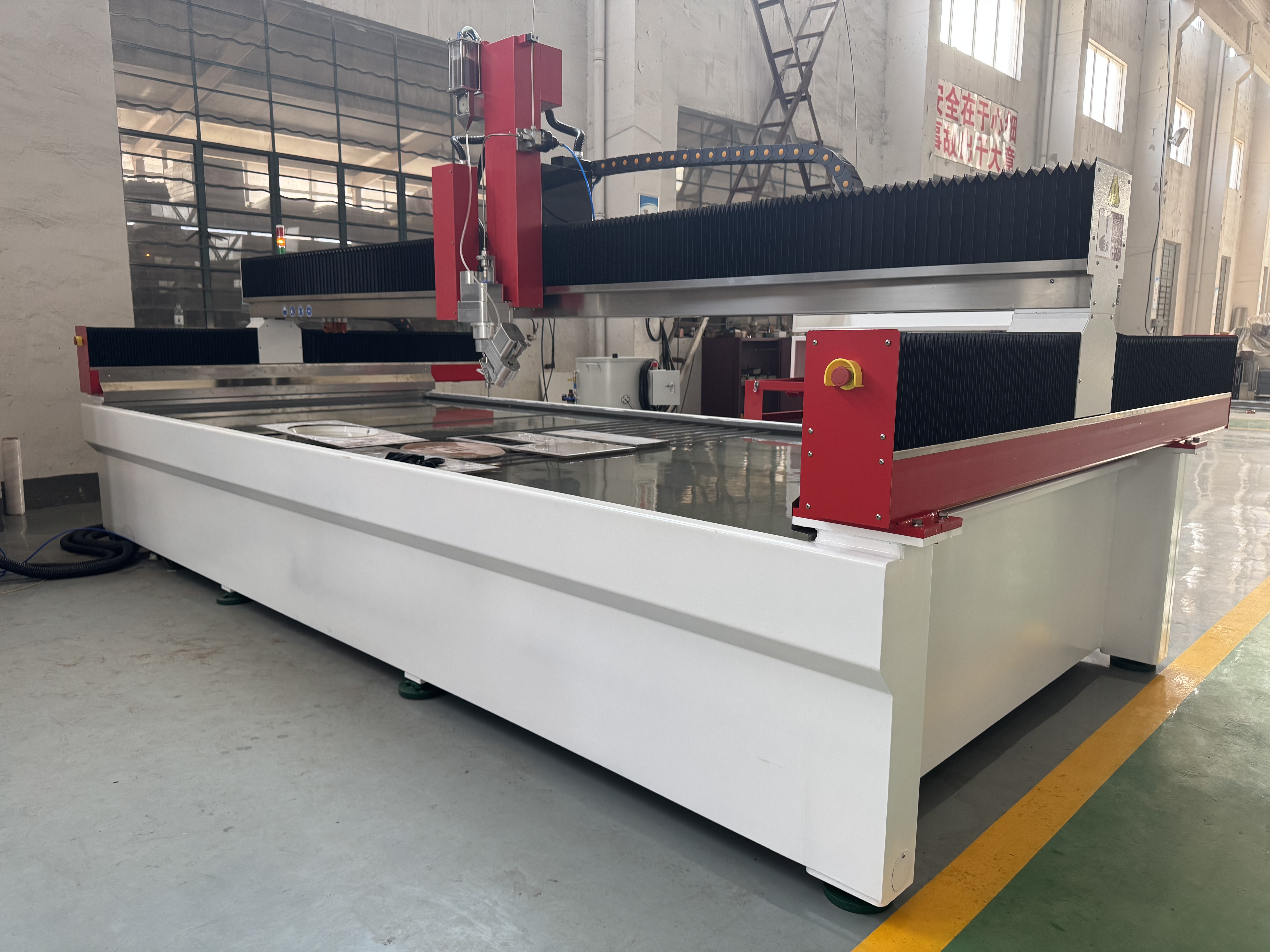

New E Series Water Jet Cutting Machine Specifically Designed For Stone

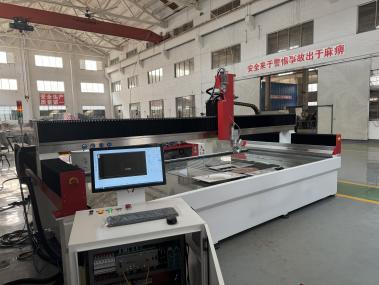

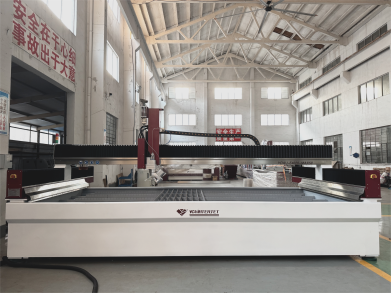

Name: YCWJ CNC E3020/E4020 Water Jet Cutting Machine

Efficient Cutting Area: 3000*2000mm/4000*2000mm

Cutting head: 3 axis / Dynamic 5-axis / Max 5-axis

Control accuracy: ±0.01mm

Positioning Accuracy: ±0.025mm

X,Y Dry-run Speed: 0-8m/min (Customizable)

Description:

CNC New E Series Water Jet Cutting Machine

• Cold Cutting, Zero Heat Damage

Waterjets utilize ultra-high-pressure water jets (with mixed abrasives) for cutting, generating no high temperatures. This fundamentally avoids the thermal effects of traditional cutting methods (such as flame and laser) that can cause cracking, discoloration, edge erosion, or damage to the stone's crystal structure. This perfectly preserves the stone's natural color, texture, and physical properties. This is the only option for precious and delicate stones (such as marble, quartz, and semi-precious stones) to maintain their pristine beauty.

• Unlimited Complex Shapes

Waterjets offer an accuracy of ±0.1mm and the ability to cut infinitely complex shapes. Whether it's intricate mosaic patterns, complex relief sculptures, or any imaginable curves and contours (such as door and window moldings and Roman columns), waterjets can easily create them. This opens up a world of creativity for designers, transforming stone from a regular geometric block into an artistic medium that can be shaped into any desired form.

• Seamless Artistry

For oversized mosaics or complex patterns, waterjets can form the work in a single process on a single sheet, eliminating the seam issues associated with traditional multiple-piece assembly. This not only enhances the overall aesthetic and overall beauty of the work, but also greatly strengthens the structural strength, creating a seamless and flawless artistic effect.

• One Machine, Endless Materials

From the softest quartz to the hardest granite, and even materials as diverse as metal, glass, and ceramic, waterjets can effortlessly cut. This powerful adaptability enables stone processing companies to easily undertake diverse, multi-material projects, achieving "one machine for multiple uses" and improving equipment utilization and market competitiveness.

• Eco-Friendly & Efficient

The primary cutting media during the cutting process are water and natural pomegranate abrasive, which produces no toxic gases or dust, significantly improving the working environment and safeguarding employee health. Furthermore, the waterjets' narrow incision (approximately 1mm) significantly reduces material waste and increases the utilization rate of precious stone, meeting the environmental and sustainable development requirements of modern manufacturing.

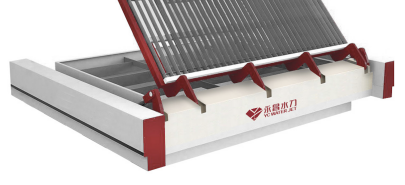

Water jet cutting table

1.(1)Effective cutting area: 3000*2000mm/4000*2000mm

(2)Running Speed

X axis:0-8000mm/min

Y axis:0-8000mm/min

2.Linear guide rail: HIWIN

Ball Screw: SHAC

3.Servo System: INOVANCE(ETHERCAT BUS CONTROL)

4.CNC Controller: CHAKONG

Waterjet Software: FlowEdge

5. Electric parts: Schneider

6.Related cables, air circuits, and other accessories

Water jet cutting head

Max5 axis cutting head

MAX Tilting angle:±60°

EtherCAT Servo System: INOVANCE

A axis:200W

C axis:400W

5-axis cutting head with laser height sensor

LASER HEIGHT SENSOR DYNAHEIGHT 2.0

The function is mainly used in cutting rock plate, stone, ceramic tile and other industries. When the materials with concave convex irregular surface or the materials are not placed horizontally on the worktable, it can ensure the constant target distance in the processing process, and improve the cutting accuracy without scratching and squeezing the surface.

YCWJ CNC E3020/E4020 Water Jet Cutting Machine | ||||

Parameters | Unit | E3020 | E4020 | |

Efficient Cutting area | mm | 3000×2000 | 4000×2000 | |

Axis travel | X | mm | 3100 | 4100 |

Y | mm | 2100 | 2100 | |

Z | mm | 150-180 | 150-180 | |

Cutting accuracy | mm | ±0.1(upper surface) | ||

Repetitive positioning accuracy | mm | ±0.025 | ||

X,Y dry-run speed | m/min | 0-15 | ||

Transmission Model | m/min | Ball screw & linear guide rail | ||

![]()

![]()

![]()

![]()

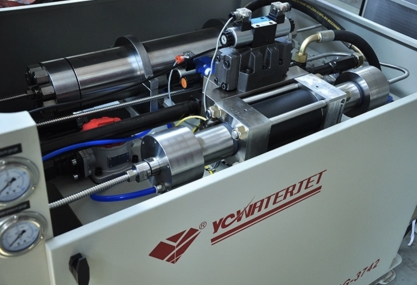

- Intensifier assembly: Main components from Accustream

- Single-row type water filtering system

- Manual pressure regulation function

- Max pressure: 4137bar(60000psi)

- Working Pressure: 340Mpa

- Star Triangle Start

- Main motor:37KW/50HP

- Max water flow: 3.7L/Min

- Main elextric components:Schneider

- PLC:Siemens

- Extra pressure auto stop and protection

- Inlet water booster pump

- Oil temperture senser

- Inlet water pressure sensor

- Three-ply safeguard(HP overpressure/over oil temperture/inlet water pressure low)

- Electrical components: Schneider

- PLC: Siemens

- Oil pressure and inelet water pressure gauge: WIKA

- Hydraulic valves & oil pump:HYTEK

CNC controller

Equipped with the FlowEdge P100/P200 waterjet cutting control system from CHAOKONG and INOVANCE servo motor system, it offers precise XY-axis positioning, ease of use, and high reliability. Its functionality is nearly identical to the CNC controller included in the standard series, but at a more affordable price.

The FlowEdge P100 is a 3axis planar cutting system primarily used for cutting materials such as glass, stone, and metal. It is also suitable for cutting glass door clamps and holes in the bathroom industry.

The FlowEdge P200 is a 5axis cutting system that supports beveling, primarily used for processing tile mosaics, slab countertops, ceramic basins, and metal parts.

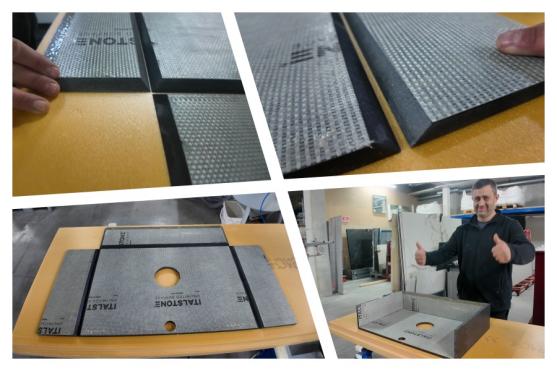

Tile mosaic pattern

Granite&marble counter top

Sink basin base

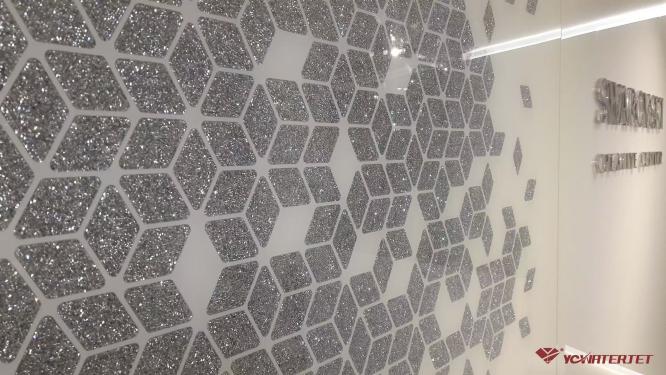

Swarovski diamonds

Notice:

The E series water jet cutting machine is specially developed by us for the stone cutting industry. Compared to the standard cutting machines, it has a lower price and lower cost. In addition to stone materials, the E series water jet cutting machines can also cut other materials such as metal, glass, carbon fiber, rubber, etc.

Pictures | Specifications |

| ABRASIVE FEEDING SYSTEM Abrasive Hopper: Dynamic sand feeding Dynamic type comes over traditional type. Manual type makes the operation easier. With the help of CNC we can control abrasive automatically Abrasive Tank: It can provide the sand consumption every time after it is filled up. Capacity: 170L |

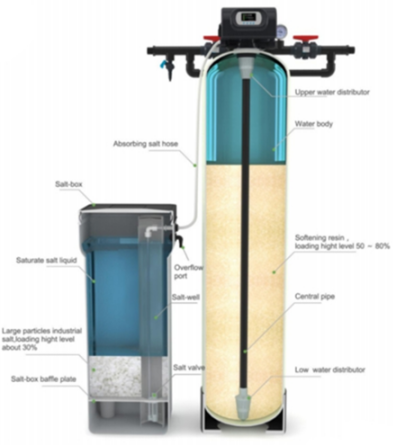

| WATER SOFTEN SYSTEM WT-2 Here are many kinds of compounds in the running water. (Calcium carbonate, carbonic acid)As the machine working, the raising of the temperature will generate some substance of the reaction of chemistry or physics-as we called it furring, which will reduce the life of the high pressure system and increase the cost. After many years’ experiences, the system can solve the problem. |

| SLUDGE REMOVAL SYSTEM SR-2 Suction pump parameters:(China) The single pump parameters Flow: 10M³/H Shoot range : 50 M Outlet pressure: 6 kgf/cm² Absord range: 7 M Maximum promise through solid part: 4.5mm Pump inlet and outlet diameter: 40mm Power:compressed air The max inlet pressure: 7 kgf/cm² The max air consume: 0.6 mm³/min Tracheal diameter:10mm Collection box: 1.6m*1.5m*1.2m |

| HYDRAULIC LOADING SYSTEM HYL400 1. Max. overturning moment load capacity: 400KG 2. The large cutting platform is hydraulically operated to overturn, which enables this hydraulic loader to load or unload an entire piece of plate while ensuring a minimum material loss and a high level of efficiency when the plate loading unit is running. |