Application of water jet in assembly line

In view of the working conditions of the assembly line, our company adopts the dual-core ultra-high pressure system with modular design, which has the ability of independent single and dual-core work.Independent communication ability, can be quickly and simply connected to the assembly line of the total control system, make it ready to use.Multi-head water cutting system design can solve the problem of service life of nozzle and sandblasting pipe. With dual-core high pressure system, one standby and one use can meet the maintenance of non-stop.

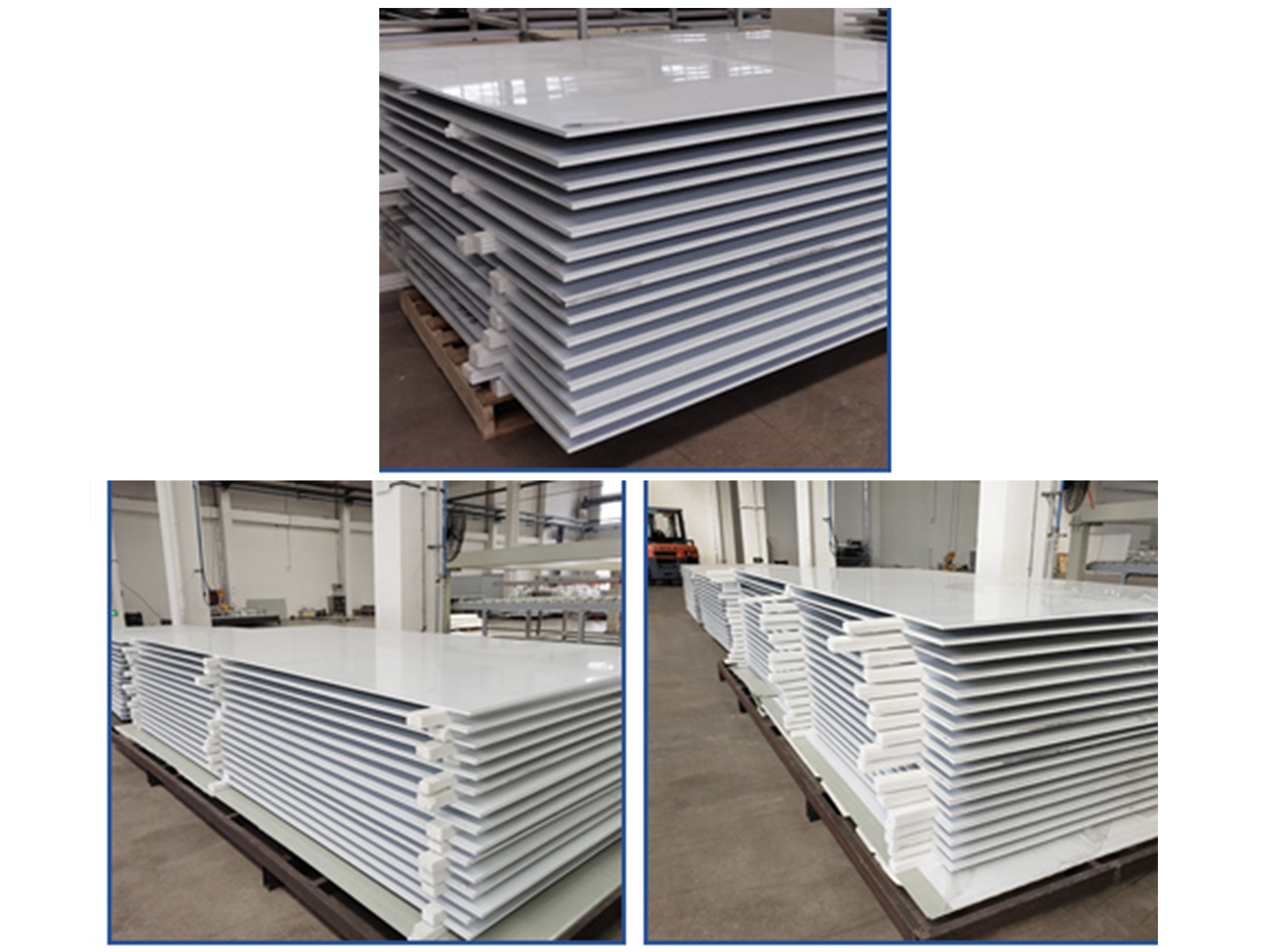

Case show:Application of water jet in PET aluminum - plastic composite material assembly line

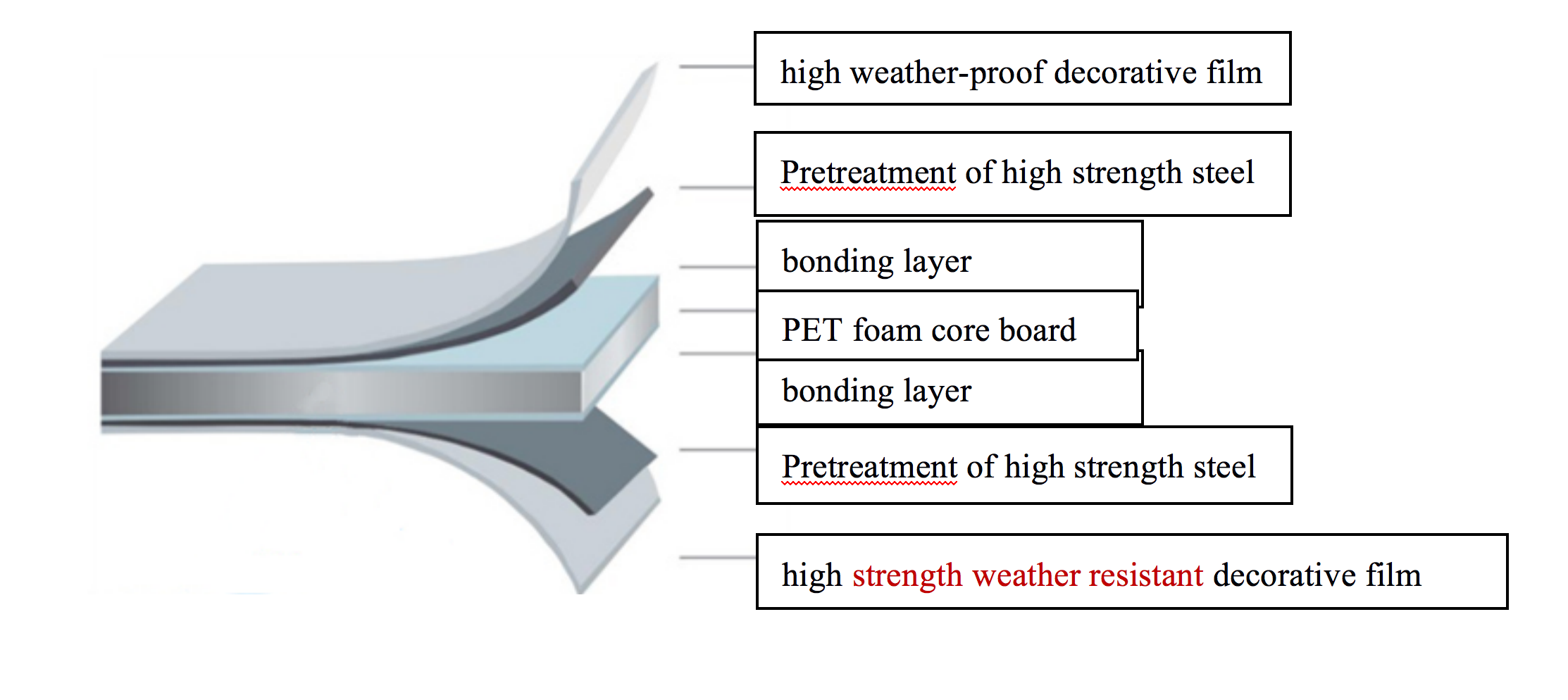

PET composite material is a new type of structural composite plate product made of metal sheet as the panel, PET invoice material as the core material, which is continuously compounded online at high temperature.Because the thermal melting point of materials in the composite layer is not consistent, the processing method of thermal cutting is obviously not suitable,the traditional processing method is usually mechanical cutting, that is, grinding wheel or saw blade cutting.This approach is prone to two drawbacks:One is incision injury, that is, the incision near the edge of the incision is stratified, torn, burr, wire drawing and other phenomena;The other is the lamination between layers, that is, the separation between layers of composite material, so that the internal structure of the component loose, reduce the strength of the component.Ultra-high pressure water cutting due to the non-contact cold processing technology, no stratification phenomenon in the processing, the material will not appear coking and hot crack.Ultra-high pressure water cutting speed, and sand cutting in the fine sand and grinding effect, so that the cutting surface smooth, smooth, accurate.