We will attend the 123rd Canton Fair on 15th-19th,April.Our booth No. is 1.1F16 We will attend the 123rd Canton Fair on 15th-19th,April.Our booth No. is 1.1F16

CNC plasma 5-axis bevel cutting machine is used for steel plate,aluminum,iron, copper and other metal materials processing with higher speed and angle compensation. For the different thickness and materials, the power supply can be adjusted accordingly. Its the best choice for the high accuracy and efficiency material cutting processing.

With 5-axis bevel cutting it has the angle compensation to solve the angle cutting for customer.

| Cutting table type | Gantry |

| Efficient cutting area(mm) | Can be customized |

| CNC control system | EDGE Pro(Hypertherm/USA) |

| Arc voltage height sensor | Sensor THC(Hypertherm/USA) |

| Bevel head system | IMA(TECNO/Italy) |

| Cutting accuracy | +/-0.01mm |

| Supply power voltage/ frequency | 380v±10%/50Hz 3PHASE/220v±10%/50Hz 3PHASE |

| Input power | 3KW |

| Compressed air | Dry, Oil free ; pressure:0.8Mpa;flow: 1.0 m3/h |

| Drive model | Mitsubishi AC servo motor |

| Rail | HIWIN liner guide rail , high-precision railway |

EDGE-Pro (Hypertherm)

* With Patented CutPro® Wizard, even new operators can be cutting production parts in less than five minutes

* On-screen Software Operator’s Console (Soft OpCon) allows easy setup and operation of cutting station and manual motion

* Integrated communications with plasma and torch height control systems deliver automated and expert control using installed

factory or custom cut charts

* Custom cut charts can be created and controlled in the part program or made available to the CutPro Wizard

* EDGE Connect runs on the Windows® 10 Enterprise operating system

Plasma power-Hypertherm

Bevel Head System (IMA TENCO/Italy)

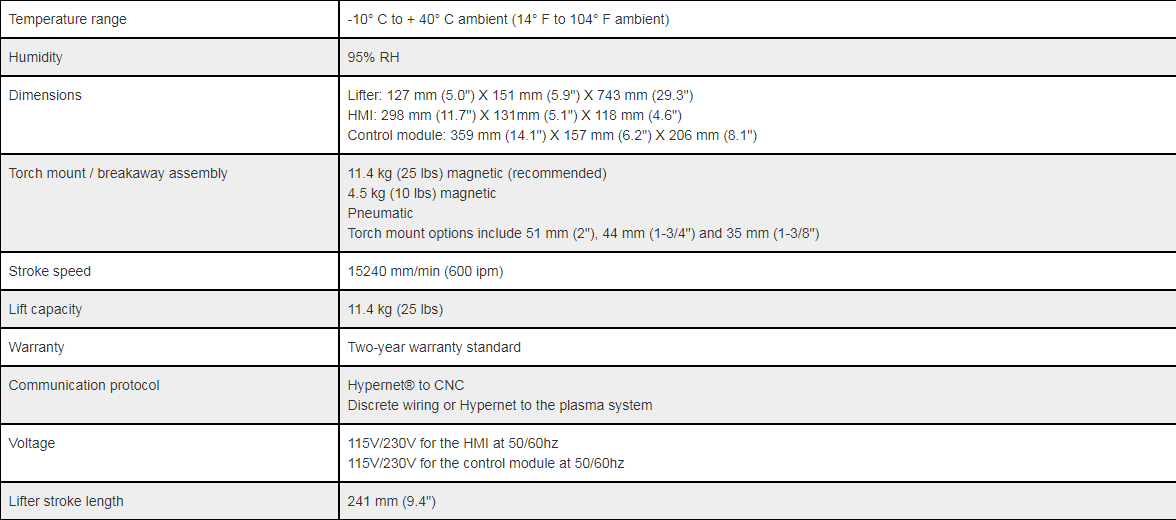

ArcGlide torch height control

Traditional torch height controls require operators to periodically adjust arc voltage to ensure proper cut height. UsingHypertherm’s proprietary techniques, the ArcGlide® torch height control (THC) continuously samples arc voltage and automaticallyadjusts arc voltage for proper torch height over the life of the consumables without requiring operator input.

The result: optimal cut quality, improved productivity and reduced operating costs for plasma cutting applications – including

True Hole® capability for HyPerformance® plasma HPRXD® installations. The ArcGlide THC is available in both CNC-integrated (with

Hypernet® communication) and standalone configurations.

Core component options

Featuring a low noise, no pollution, high precision and high reliability

Unique design of this water jet cutting machine makes the installation and the maintenance easier.Stable working pressure to ensure the working efficiency.