We will attend the 123rd Canton Fair on 15th-19th,April.Our booth No. is 1.1F16 We will attend the 123rd Canton Fair on 15th-19th,April.Our booth No. is 1.1F16

Views: 0 Author: Site Editor Publish Time: 2020-10-21 Origin: Site

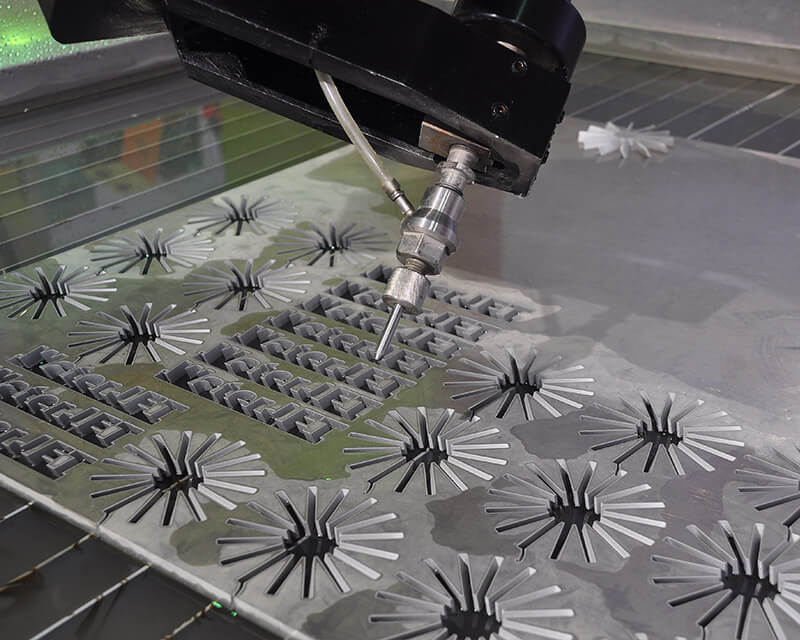

In recent years , with the rapid development of mechanical industry and higher precision machine platform ,

the waterjet cutting machine has been widely applied in a wider range of metal processing fields.

It has powerful computer-aided design and better control functions ,especially automatic deceleration when cutting ‘sharp corners or edges’.In addition,the waterjet cutting machine is good at grinding ,it greatly improves the quality and efficiency of cutting .Besides that,it also can work directly on metal parts to complete shaping and cutting processes.

In the metal industry,the pursuit of high-quality and efficient forming processing is the international development trend in recent years. With the emergence of precision ball screws,servo motors and other technologies,the waterjet cutting machine can complete higher position accuracy,revise clearance compensation and improve the accuracy of repeated positioning.The manufacture devoted more energy to analyzing the causes of the geometric error.High-precision measuring instruments such as the club measuring instrument , the laser interferometer,and the error mapping table are used to improve the accuracy correction.

Improving the energy of water jet will improve the ability of water jet cutting .The pressure and maximum output flow of the waterjet cutting machine are the main parameters affecting the cutting capacity.Further research and experimentation have been carried out internationally.The test proves that even the pressure reaches more than 700MPa,thin steel plates and hard composite materials can be cut with clean water.Improving the pressure of the supercharger can greatly improve the cutting ability of water jet.On the other hand,under the same pressure,increasing the power of water jet can also improve the cutting capacity.Under what circumstances,multi-charger parallel technology is invented.This is the use of multi-supercharger parallel technology without major changes to the existing system.When two or more high voltage generators are used in parallel,the output flow of the turbocharger can be increased easily.Using a large diameter nozzle for cutting ,so the water jet cutting energy is more effective,the cutting effect will be better.

It is well known that lasers, plasma and other cutting methods have the effect of energy gradient.The deeper the slit,the weaker the cutting ability.The cutting surface is often not perpendicular to the work piece surface,which is called the cutting slope.It is an inherent defect of all cutting methods.Although the cutting slope can be partially reduced by increasing the cutting energy or reducing the cutting speed,there is still a problem that it can not be completely vertical.The five-axis waterjet cutting technology of the waterjet cutting machine adds two rotating shafts to the original three-axis platform to realize the waterjet cutting machine can swing in any direction.Using the slope model preset in the system,through the real-time calculation of the cutting trajectory,then modification considering the material and thickness of the work piece.By continuously swinging the cutting head during the cutting process, the work piece reaches a perfect non-slope state.

Several Simple Methods of Preventing Abrasive Clogging in Water Jet Cutting Machine

Water jet cutting machine is the best way to cut stainless steel

Application of Water Jet Cutting in Composite Material Cutting

Ultra-high pressure water jet cutting 150mm thick rock wool with pure water

Amazing Swarovski hall processed by YC waterjet cutting machine