We will attend the 123rd Canton Fair on 15th-19th,April.Our booth No. is 1.1F16 We will attend the 123rd Canton Fair on 15th-19th,April.Our booth No. is 1.1F16

Views: 0 Author: Site Editor Publish Time: 2020-07-07 Origin: Site

The water required by waterjet cutting machine is generally ordinary water, but the importance of good water quality can not only help to improve the reliability and service life of pump seals and valves, but also have a significant role in extending the life of nozzles and generating efficient water jet.

The working pressure of the equipment is very high and the nozzle is very small. Some small particles of impurities and scaling in the raw water and corrosion ions will have a certain impact on the service life of the equipment. Therefore, the raw water must be treated before it can be supplied for cutting.

In order to ensure the normal operation of pumps, valves, seals and nozzles, filter should be set at the inlet of the pump. When the cleanliness of the water is very low, multi-stage filtration should be considered. Due to the loss of filter resistance, sufficient pressure should be ensured at the inlet of the filtration system. If necessary, a front centrifugal pump can be installed to ensure that the suction system does not occur cavitation and maintains continuity of attraction.

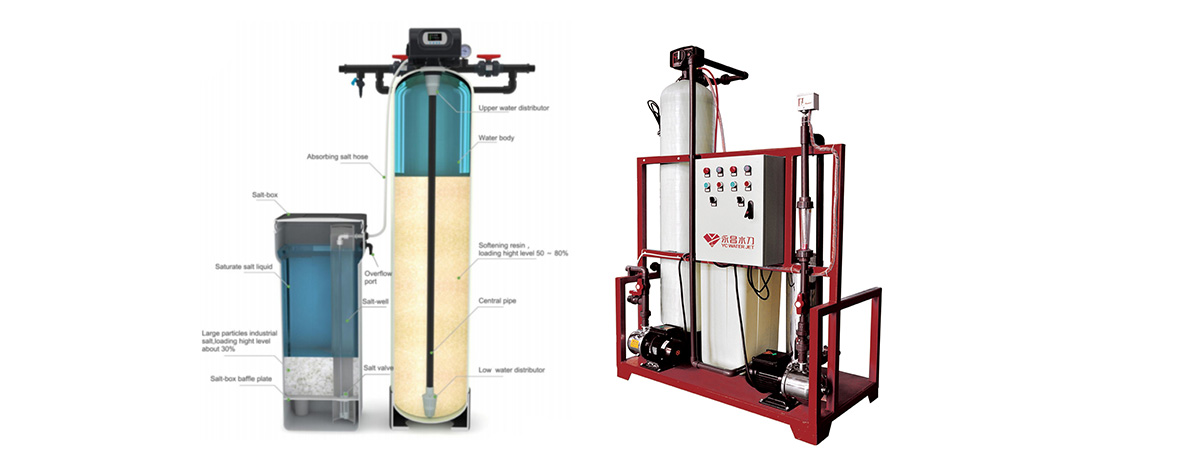

Actually, the treatment of water quality is related to the raw water quality ,the life time of nozzle and the consistent working of waterjet cutting machine. The devices to process water quality are water soften system, water purification device and water dissociation device.

In different areas of our country,there are a lot of differences in water quality.For example, the content of Ga+ and Mg+ in water is relatively high in most northern areas ,which is the so-called "hard water". the waterjet cutting machine will wear and tear from this kind of water quality. Therefore, water quality has a great influence on waterjet cutting machine.

The preliminary treatment of water by waterjet cutting machine includes water filtration and water softening. The purpose of water filtration is mainly to eliminate tiny impurities and suspended solids in water. Water filtration is usually achieved by using multi-stage series filter devices. Water filtration is equipped with three layers of filtration equipment. After three layers of filtration, there will be no suspended matter in the water. The processed water enter the supercharger after being boosted by the booster pump. The filter usually needs to be equipped with a pressure difference gauge. When the filter element is blocked by the filter and the water pressure is insufficient, the system will automatically stop and alarm, reminding the operator that the filter element should be replaced in time to ensure the safety of the system.Methods of softening water usually include boiling, ion exchange and reverse osmosis. The resin used in the water soften system can effectively remove calcium and magnesium ions in the water, thereby achieving the effect of softening the water. And the water soften system has an automatic regeneration function,which can not only remove residual chlorine and suspended matter in the water, but also better and effectively guarantee the service life of the resin.